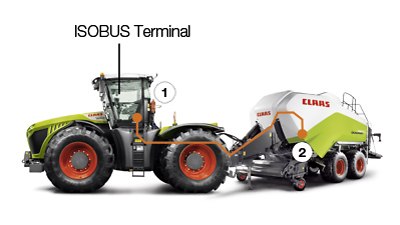

ISOBUS.

- ISOBUS terminal to control the functions of multiple implements

- Many implement functions can be accessed via the function keys on the armrest

- ISOBUS connections at front and rear

Signals such as speed, lower link position and PTO speed are provided in a standard format. ISOBUS also standardises, and therefore simplifies, communication between the implement and farm management software.

Components of the ISOBUS system:

An ISOBUS system comprises the following components:

- ISOBUS-compatible terminal

- Tractor equipped with ISOBUS

- Implement equipped with ISOBUS

TIM (TELEMATICS on Implement)

- TIM uses the operating parameters of an attached agricultural machine to control the tractor's forward speed through the ISOBUS interface.

- For the first time in a square baler-tractor combination, TIM makes it possible to operate the baler at optimum performance all the time by means of automatic forward speed control. Two operating modes are available: "maximum performance" and "maximum bale quality".

- The PTO automatically switches off if a unit malfunctions or is overloaded.

- Implement and tractor form a single, automatically controlled unit

- Our implement manufacturing partners are already working on an implement-specific adaptation

- Tractor electronic control unit

- Implement electronic control unit

The benefits for you:

- Optimisation of overall machine operation

- Maximum performance throughout the work process

- Reduction in damage

- The large number of interactions is reduced to a minimum, which reduces the driver's workload

- Optimum fuel consumption throughout the work performed